The advantages of Dead-weight tester (or pressure balance) are excellent long-term stability, small measurement uncertainty, good repeatability and excellent reproducibility.

Therefore, national standard laboratories, calibration institutions, research institutes and industrial calibration laboratories have used it as the primary pressure calibrator for a long time.

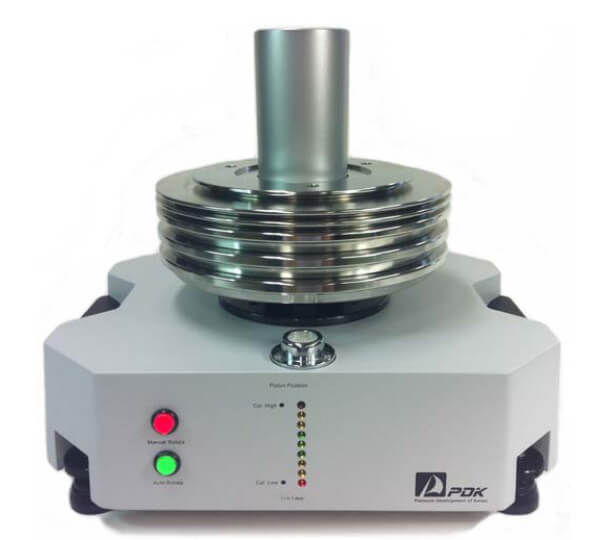

PDK’s Dead-Weight Tester PDPG is the result of precision machining technology and high electronic engineering technology. PDPG is proud to show an advanced concept of pressure calibrator. PDPG boasts the highest performance among equivalent models

PDK’s Dead-weight Tester PDPG is suitable to test and calibrate various kinds of pressure gauges including pressure transducers, digital manometers, pressure transmitters, pressure switches. PDPG was made in accordance with the regulations of Pressure Balance International Recommendation (OIML R110, 1994(E)).

Dead-Weight Tester is used as a generator of an accurately known pressure. It measures pressure as force per unit area. Therefore, Dead-Weight Tester is the most accurate pressure calibrator.

Specification

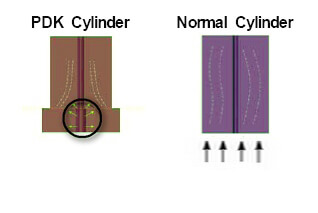

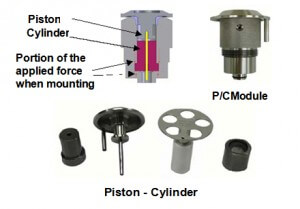

Wing type P/C is the most optimized and modernized design for piston-cylinder unit.

A protrusion on the cylinder face enables easy and firm installation to the mount. Unique end shape of cylinder hole assures excellent metrological characteristics.

PDK’s patented cylinder (Korea, 10-0449151) is made of tungsten carbide. PDK’s piston-cylinder shows high precision and stability. The modular piston-cylinder unit can be replaced by hands very easily and quickly without special tool. It also has excellent structure which prevents environmental contamination from outside.

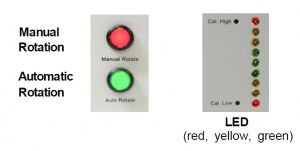

In order to monitor the float position of piston, non-contact height sensor was developed. In total 9 LEDs are attached on the front panel of PDK’s PDPG. Each LED will be lighting at 1 mm interval according to piston movement.

When green LED is shining, it indicates “measurement available.”

In order to rotate piston, two methods are available. The first one is to press the red button on the front panel of PDPG. The piston can be rotated only when you want to rotate. Second method is to press the green button.

When the piston is located in a suitable operation position, the piston rotates automatically. The operation interval covers ±3 mm from reference float line. If out of range, piston stops automatically.

Optional mass set (and trim mass) is available.

For Hydraulic, pressure generator / controller consists of pump priming pump and a precision spindle pump.

O-ring designed for high-pressure structure of almost no internal leakage, a torque of the lowest among the same class and during long-term use, it will needs less power in high pressure up to more than 200 MPa.

Available installed pressure generator / controller which is special designed by PDK.

Specification

For Dead-weight Tester, Comparator and comparison tester.

Specification

For Dead-weight tester, Comparator and Comparison Tester

Specification

For Dead-weight tester, Comparator and Comparison Tester

Specification

For Dead-weight tester, Comparator and Comparison Tester (Precision control)

Specification

PDK Co., Ltd. was founded in 1994 as Piedindore Korea. It has been growing continuously based on customer's trust. With the continuous interest and encouragement of our customers, we have grown to become a professional company based on years of field experience, technology and know-how in measuring equipment field.

Especially, our measuring instrument business unit has steadily received technical consultation from overseas advanced technology manpower, and we can promise high quality management and provide maximum satisfaction and thorough service for optimizing and quality of measuring instrument performance through continuous post management We are working hard.

Lastly, we will continue to provide support to our customers with high-quality service and reasonable price policy for customer satisfaction so that we can contribute to domestic industry development. Thank you.